Description

Circuit connection

Recommended pad

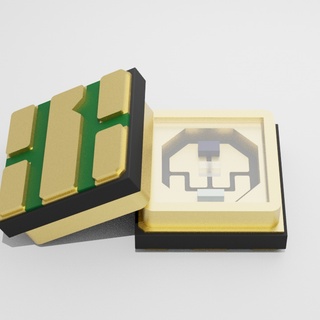

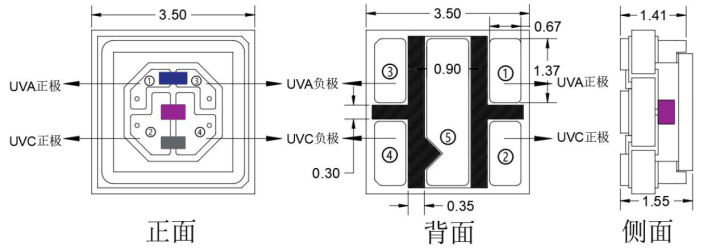

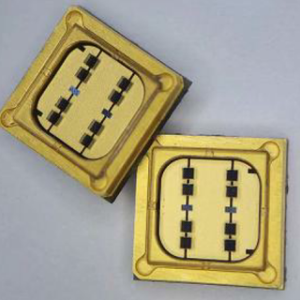

- A single device contains three different kinds of chips, which are UVA / UVC / zener diodes. The zener diode plays an ESD protection role on UVC led;

- As shown in the above figure, ①is the UVA positive electrode, ② is the UVC positive electrode, ③ is the UVA negative electrode, and ④ is the UVC negative electrode; ⑤ It is a heat dissipation pad;

- Zener faces downwards, with the positive pole on the left and the negative pole on the right. The missing corner on the back indicates the negative pole;

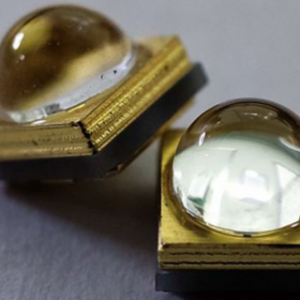

- Due to different batches of brackets, there may be slight differences in the physical appearance. Products with different appearances are compatible with each other and do not affect their use;

- Drawing unit: mm, unless otherwise specified, dimensional tolerance is ± 0.20 mm

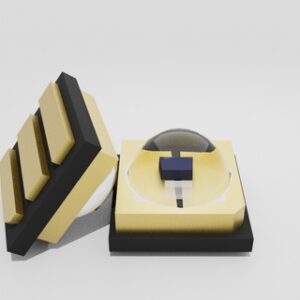

- Package: 3535 package, external dimension: 3.5 × 3.5 × 1.55 (L × w × h) [unit: mm]

- Package material: aluminum nitride ceramic bracket, plane lens

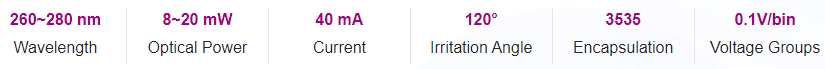

UVC photoelectric parameters and spec range (@ 40mA, Ta = 25 ℃, Rh = 30%)

| Item | Symbol | Min. | Typ. | Max. | Bin | Unit |

|---|---|---|---|---|---|---|

| Peak wavelength | λp | 260 | / | 280 | Such as groups | nm |

| Optical power | P0 | 8 | / | 20 | / | mW |

| working voltage | Vf | 5 | / | 7 | 0.1 | V |

| Driving current | If | / | 40 | / | / | mA |

| Irritation angle | 2θ1/2 | / | 120 | / | / | deg. |

| FWHM of wave crest | Δλ | 7 | / | 13 | / | nm |

| thermal resistance | RΘj-b | / | 20 | / | / | ℃/W |

Wavelength range

| Groups | W01 | W02 |

|---|---|---|

| Wavelength (nm) | 260~270 | 270~280 |

Optical power range

| Groups | P025 | P053 | P054 |

|---|---|---|---|

| Optical power (MW) | 8~10 | 10~15 | 15~20 |

Voltage range

| Groups | V11 | V12 | V13 | V14 | V15 | V16 |

|---|---|---|---|---|---|---|

| Voltage (V) | 5.0~5.1 | 5.1~5.2 | 5.2~5.3 | 5.3~5.4 | 5.4~5.5 | 5.5~5.6 |

| Groups | V17 | V18 | V19 | V1A | V1B | V1C |

| Voltage (V) | 5.6~5.7 | 5.7~5.8 | 5.8~5.9 | 5.9~6.0 | 6.0~6.1 | 6.1~6.2 |

| Groups | V1D | V1E | V1F | V1G | V1H | V1I |

| Voltage (V) | 6.2~6.3 | 6.3~6.4 | 6.4~6.5 | 6.5~6.6 | 6.6~6.7 | 6.7~6.8 |

| Groups | V1J | V1K | ||||

| Voltage (V) | 6.8~6.9 | 6.9~7.0 |

Limit conditions

| parameter | Symbol | numerical value | Company |

|---|---|---|---|

| power waste | Pd | 420 | mW |

| Forward current | If | 60 | mA |

| Forward voltage | Vf | 5~7 | V |

| Service temperature | TOPR | -30~60 | ℃ |

| Storage temperature | TSTG | -40~100 | ℃ |

| Junction temperature | Tj | 80 | ℃ |

| Static electricity (human mode) | ESD | 2000 | V |

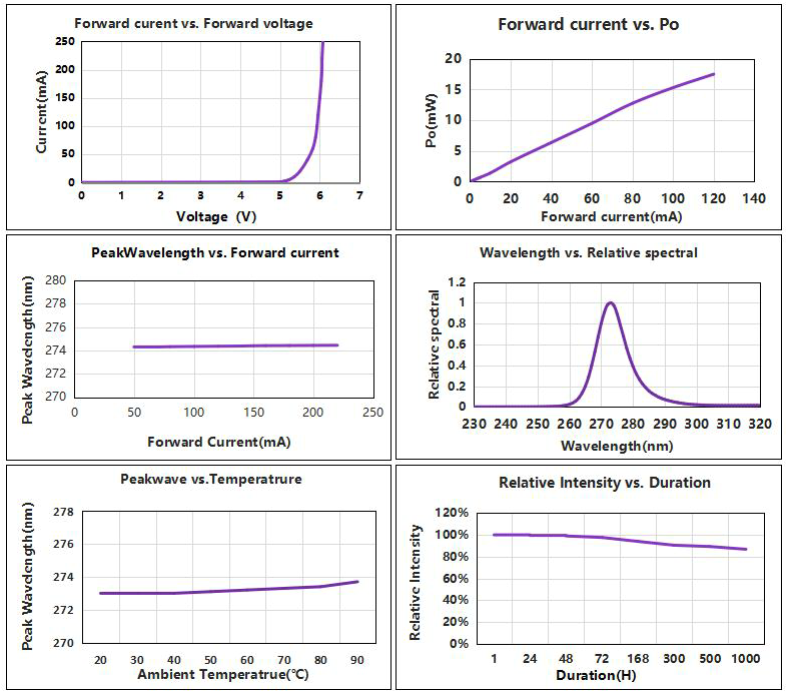

- Optical power refers to the total optical output power collected by integrating sphere;

- The measurement errors of forward voltage, peak wavelength and radiation power are ± 0.2V, ± 3nm and ± 10%, respectively. The increase of injection current will lead to temperature rise, The light attenuation of LED lamp beads will be accelerated, and the service life will be shortened; when the LED lamp beads are tested or used beyond the above limit values, the reliability of the device may be affected and permanent damage may be caused.

- It is recommended to provide a good cooling environment or cooling system to obtain the best effect.

- The above test data are from DUVTek, and the actual curve will be different depending on the sampling situation.

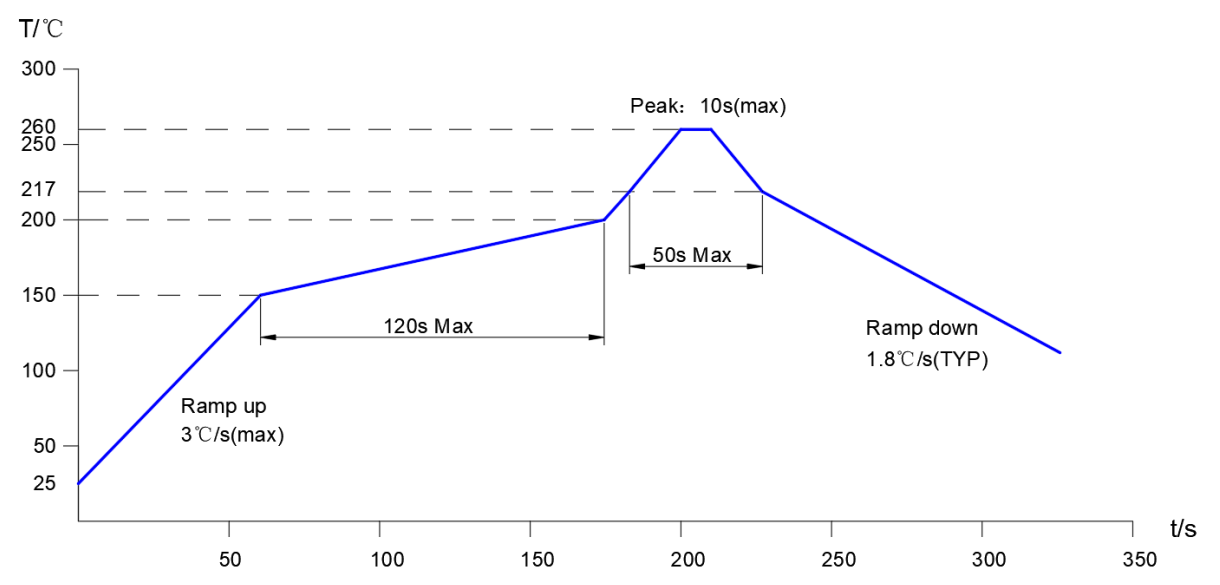

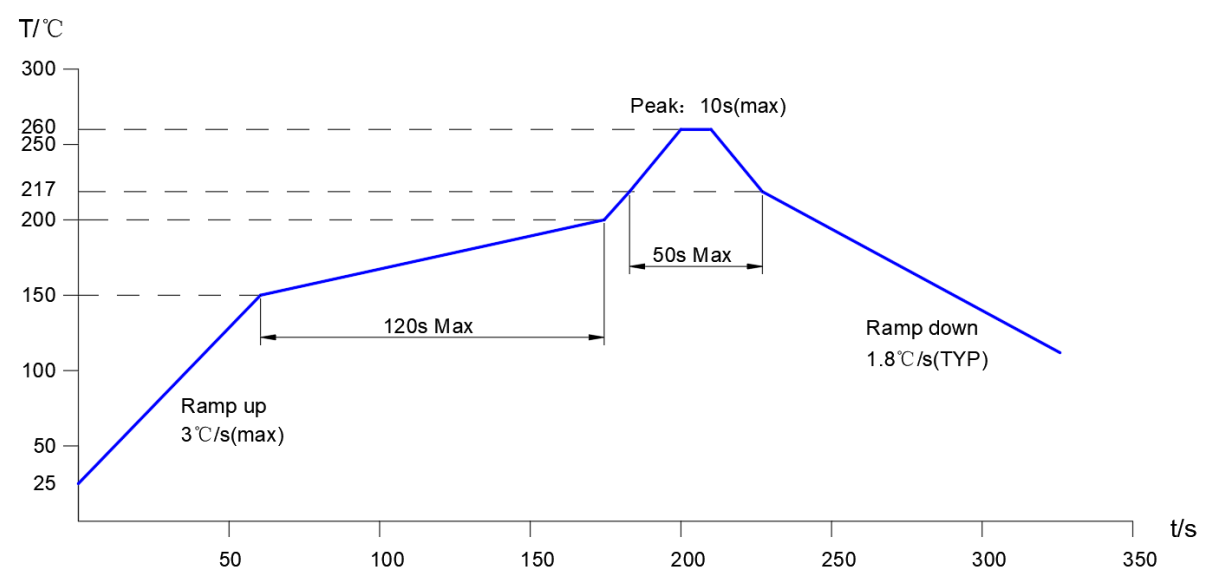

- The patch shall be reflowed with environment-friendly solder paste,The peak temperature should not be greater than 260 ℃The peak time should be controlled within 10 seconds, and the reflux time should not exceed 8 minutes.

- Reflow welding should not be more than once;

- It is not recommended to repair after welding dark purple led. When repair is inevitable, double head soldering iron must be used, and the product itself should not be damaged while operating carefully;

- When welding, do not apply pressure on the deep UV LED during heating;

- It is recommended to use convection reflow welder with temperature above 7.

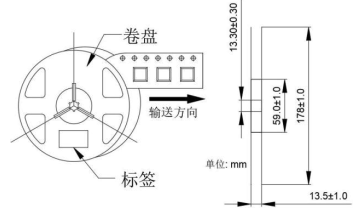

Packing instructions

| Carrier | |

| Reel | |

| Aluminum foil bag packaging |

- The camber angle of the carrier is not more than 1 mm / 100 mm, and the length is 250 mm;

- All dimensions meet eia-481-b requirements;

- Materials: conductive polyester polystyrene plastic.

Label description

| label | interpretation |

|---|---|

| TYPE | |

| SPEC | Wxxpxxxvxxa1, please refer to spec scope for specific meaning |

| LOTS | Batch number |

| QTY | number |

| Date | date |

| Test items | experimental condition | standard | Failure ratio |

|---|---|---|---|

| Normal temperature aging | T = 25 ℃, calibration current, continuous lighting for 1000 hours | ΔPo≤15%,ΔVF≤20% | 0/10 |

| Thermal Shock | -300 cycles of cold and hot shock at 40~+100 ℃, 30min/cycle | ΔPo≤15%,ΔVF≤20% | 0/10 |

| Antistatic | R=1.5kΩ, C=100pF,Voltage level=2kV | ΔPo≤15%,ΔVF≤20% | 0/10 |

- All assembly workers, observers and bystanders must have eye and skin protection;

- It is forbidden to observe with naked eyes (including through microscope) and handle deep UV LED naked in operation;

- Do not touch the optical structure of the deep UV lamp bead;

- This product is a humidity sensitive product, the recommended storage temperature is 18 ℃~ 30 ℃, the humidity is 30% ~ 60%, and sealed. In order to ensure the product quality, it is recommended to use it within one year after leaving the factory if the outer packing bag is not opened; if the outer packing bag is opened, it is recommended to use it within 24 hours, and re seal it for storage after 24 hours. Dehumidification measures should be taken before the next use: temperature: 65 ℃ time: 5h.

Reviews

There are no reviews yet.